-

Abstract

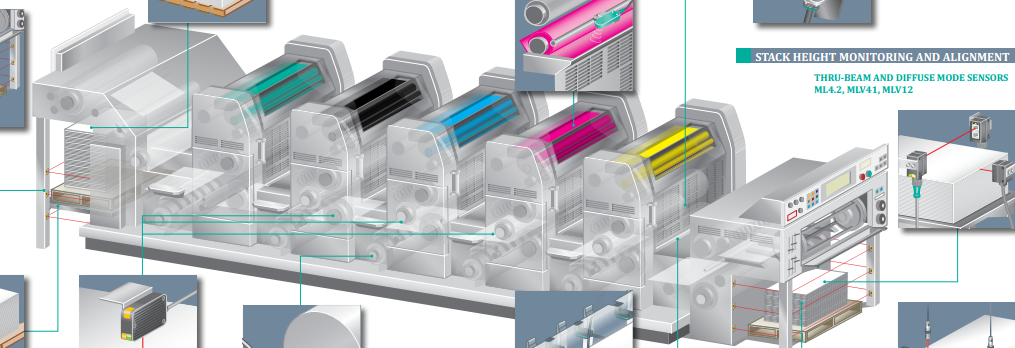

The paper gives a review about the possibilities of using Big Data technologies in the print industry. Current situation and research are presented with a brief overview and description of the data mining process. Process parameters readouts and process modelling by using problem-solving methods open up new possibilities for production efficiency. Different authors have provided solutions for print and print quality related problems by data collection through sensor readouts and real-time monitoring of different production system variables. Major production techniques (offset and flexo printing) have been partly investigated and monitored through closed inline controls, or metadata communication with the use of Job Definition Format. The researchers have found possibilities in solving particular print or production related issues with the use of Big Data techniques or its subsets, but still, no integrated market ready solution exists. A theoretical framework for a corrugated production factory is shortly presented, outlining possible applications and connections for a fully integrated data mining system that could bring the Industry 4.0 in the printing sector.

-

-

Study of correlation between ink trapping and color difference in overprint

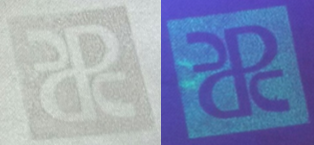

The ink trapping value is one of the important parameters affecting the appearance of secondary colors in overprint. Usually, the ink trapping parameter is traditionally calculated based on the solid density values of the primary colors and the overprint color. These density values are measured by the complementary color filter of the color final ink layer, and these ink trapping values can be calculated using the Preucil, Ritz, or Brunner formulas. Furthermore, the density measurement is more suitable for testing the color printing and not for overlapping assessment because these density values are measured by the complementary color filter of the second color ink. The ink has a specific transmittance, and light is not only absorbed but also scattered inside the ink layer, so the total density of the overlapping colors will be less accurate. As a result, the color measurement method is used to describe the effect of ink trapping of the second ink layer on the first layer of ink. The main idea is to use the color difference value to evaluate the ink trapping ability. In this paper, the author has quantitatively analyzed the correlation between the percentage value of ink trapping and the color difference parameter ΔEab*. The studied results show that the ΔEab* value has a linear correlation with the ink trapping value calculated according to the traditional methods based on density values. This result is also aimed at the fluctuant tolerance of ink trapping ratio during four-color printing to achieve the standard color value quickly.

-

Là nhiệm vụ khoa học và công nghệ cấp Thành phố do Trung tâm Phát triển Khoa học và Công nghệ Trẻ chủ trì thực hiện, ThS. Nguyễn Thành Phương Khoa In & Truyền thông - Trường Đại học Sư phạm Kỹ thuật TP.HCM làm chủ nhiệm, Sở Khoa học và Công nghệ TP.HCM nghiệm thu năm 2019.

-

-

-

Nhân dịp kỷ niệm 30 thành lập Khoa In & Truyền thông (1987 – 2017), sáng ngày 8/12/017 Khoa In & Truyền thông sẽ tổ chức Hội thảo Khoa học Quốc tế về Công nghệ In, Bao bì và Xu hướng phát triển.

-

-

3D printing -- also known as additive manufacturing -- turns digital 3D models into solid objects by building them up in layers. The technology was first invented in the 1980s, and since that time has been used for rapid prototyping (RP). However, in the last few years, 3D printing has additionally started to evolve into a next-generation manufacturing technology that has the potential to allow the local, on-demand production of final products or parts thereof.

-

| |